- English

- Farani

- Kelemānia

- Pukiki

- Paniolo

- Lūkini

- Japanese

- Korean

- Alapia

- Helene

- Kelemānia

- turkish

- Ikalia

- kolaila

- Lomania

- 'Inidonesia

- Czech

- 'Apelikānā

- Kuekene

- Polish

- Pōkē

- Catalan

- Esperanto

- Hindi

- Lao

- Alabania

- Amahapika

- Armenian

- azerbaijani

- Hawaiian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Hawaiian

- Koalia

- Hōlani

- 'Esetonia

- filipino

- Pinilana

- Hawaiian

- Kalikia

- Keokia

- Kuhalaki

- Haitian

- Hauka

- aloha

- Hebera,

- Mona

- Hunakalia

- 'Āina Hau

- igbo

- 'Ōlelo Kava

- Kanākā

- kazakh

- khmer

- Kurdish

- Kyrgyz

- Lakina

- Lakiwiana

- ʻŌlelo Lituania

- Luxembou..

- Teselonike i

- 'Ōlelo Malagasy

- Mālei

- X.

- Malkī

- XIV.

- Malapi

- mongolian

- Pulumi

- Nepali

- Norewai

- ʻŌlelo Pashto

- Persian

- punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- somali

- Sâmoan

- Hawaiian Hawaiian

- Shona

- Kiniki

- Sundanese

- Swahili

- tajik

- Tamil

- Keluku

- Thai

- Ukrainian

- Urdu

- uzbek

- Wiekanama

- Welsh

- xhosa

- Hawaiian

- Hawaiian

- Zulu

1. Introduction to Conveyor Components: Hoʻopili nā ʻāpana Conveyor i nā ʻano mea like ʻole e hana pū ana e hana i nā ʻōnaehana conveyor hana. Aia kēia mau ʻāpana i nā wili, nā kāʻei, nā pulleys, nā bearings, a me nā mea pono, e lawelawe ana kēlā me kēia i kahi hana kikoʻī i ke kaʻina hana. Mai ke alakaʻi ʻana a me ke kākoʻo ʻana i ka hoʻokele a me ka hoʻokele ʻana, pāʻani kēia mau ʻāpana i nā kuleana koʻikoʻi i ka hana maʻemaʻe a maikaʻi o nā ʻōnaehana conveyor.

2. Nā ʻano a me nā hana o nā ʻāpana Conveyor:

Nā Rollers: ʻO nā Rollers ke kumu o nā ʻōnaehana conveyor, kākoʻo a alakaʻi i ka neʻe ʻana o nā waiwai ma ke ala conveyor. Hele mai lākou i loko o nā ʻano hoʻonohonoho like ʻole, me nā wili gravity no ka lawe lima lima a me nā wili ikaika no nā ʻōnaehana automated.

Nā kāʻei: ʻO nā kāʻei conveyor he mau puka lou no ka lawe ʻana i nā waiwai mai kekahi wahi a i kekahi. Hana ʻia lākou mai ka lāʻau, PVC, a i ʻole nā mea ʻē aʻe a loaʻa i nā hoʻolālā like ʻole e kūpono i nā noi kikoʻī, e like me nā kāʻei paʻa, nā kāʻei modular, a me nā kāʻei manawa.

Pulleys: ʻO nā pulleys nā ʻāpana cylindrical i kau ʻia ma nā wēlau o nā kāʻei conveyor e maʻalahi i ka hoʻololi a me ka neʻe. Hele mai lākou i nā ʻano nui a me nā hoʻonohonoho like ʻole, me nā pulleys drive, idler pulleys, a me snub pulleys, e lawelawe ana kēlā me kēia i kahi kūlana kūʻokoʻa i ke kāʻei ʻana a me ka alignment.

Bearings: Pono nā bearings no ka hoʻohaʻahaʻa ʻana i ka friction a me ka hoʻomaʻamaʻa ʻana i ka hoʻololi maʻalahi i loko o nā mea conveyor e like me nā wili a me nā pulleys. Hele mai lākou i nā ʻano like ʻole, e like me nā bearings ball, roller bearings, a me nā lima lima, i koho ʻia ma muli o ka hiki ke hoʻouka, ka wikiwiki, a me nā kūlana kaiapuni.

Nā mea komo: Nā mea hoʻokele, e like me nā alakaʻi, nā kiaʻi, nā ʻike, a me nā mana, e hoʻonui i ka hana, palekana, a me ka pono o nā ʻōnaehana conveyor. Kōkua lākou i ka pale ʻana i ka waiwai, pale i nā limahana, a hiki i ka hana automated ma o ka hoʻohui ʻana o nā sensor a me nā ʻōnaehana mana.

3. Koʻikoʻi o nā ʻāpana Conveyor: He kuleana koʻikoʻi nā ʻāpana conveyor i ka hana holoʻokoʻa a me ka hilinaʻi o nā ʻōnaehana conveyor:

Pono: Hoʻohui nā ʻāpana kiʻekiʻe i ka hilinaʻi a me ka uptime o nā ʻōnaehana conveyor, e hōʻemi ana i ka pilikia o ka downtime i hoʻolālā ʻole ʻia a me ka mālama nui ʻana.

Palekana: Hoʻonohonoho pono ʻia a mālama ʻia nā mea conveyor e hōʻoia i ka hana palekana, e hōʻemi ana i ka pilikia o nā ulia a me nā ʻeha i nā limahana.

Hoʻololi: ʻAe nā ʻāpana conveyor modular no ka hana maʻalahi a me ka hoʻololi ʻana i ka hoʻololi ʻana i nā pono hana, hiki ke hoʻohana pono i nā mea waiwai i nā noi like ʻole a me nā ʻoihana.

4. Maintenance a me ka Optimization: Pono ka mālama mau a me ka nānā ʻana no ka hōʻoia ʻana i ka lōʻihi a me ka hana maikaʻi o nā mea conveyor. Hoʻopili kēia i ka lubrication, ka nānā ʻana i ka alignment, ka hoʻopaʻa ʻana i ke kāʻei, a me ka hoʻololi ʻana i nā ʻāpana ʻeha a poino paha. Ma ka hoʻokō ʻana i nā hana mālama pale a me ka hoʻohana ʻana i nā ʻenehana holomua e like me ka mālama wānana a me ka nānā ʻana i ke kūlana, hiki i nā ʻoihana ke hōʻemi i ka downtime a hoʻonui i ka pono o ka ʻōnaehana conveyor.

ʻO ka mea hoʻolele ʻōuʻu ʻōuʻu

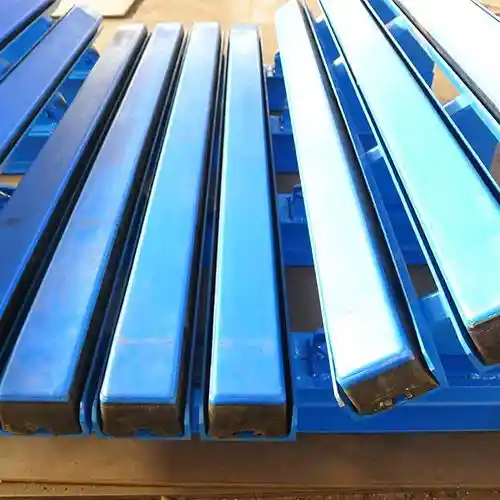

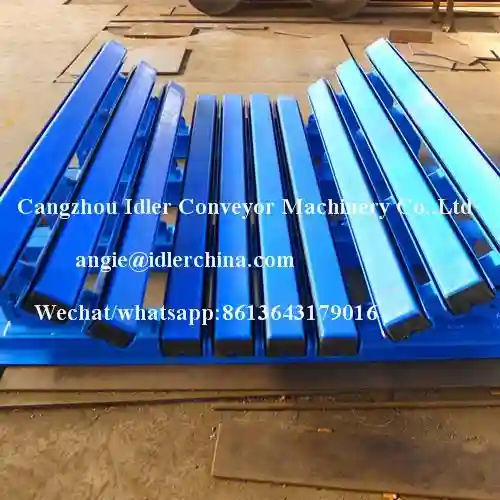

Nā hiʻohiʻona: 1.variable-angle trough (groove angle he 20 °, 30...

nānā i More

Moe Hoʻopiʻi Kāʻei Kūʻai

Mea Hoʻopono Moena ʻO ke kāʻei conveyor: pale ʻana i ka corrosion Abs...

nānā i More

Moena Impact No ka Belt Conveyor

ʻO kahi moe impact no ka Belt Conveyor Pōmaikaʻi: Pale ʻino...

nānā i More